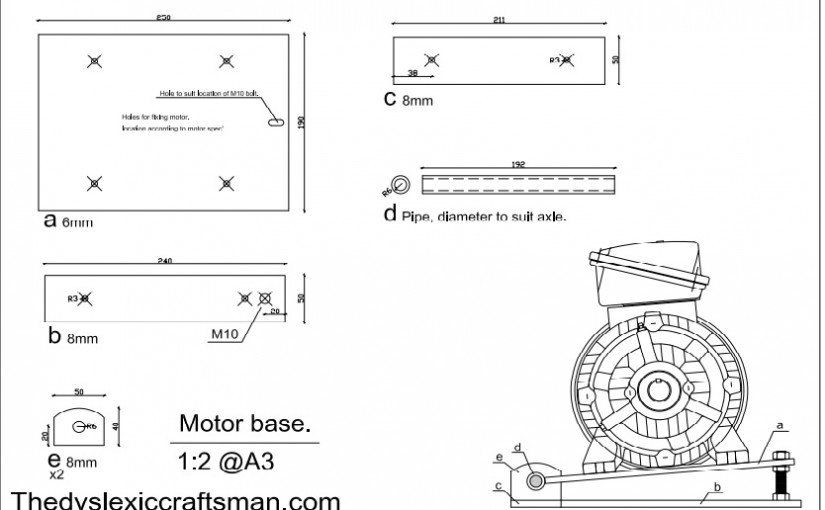

Building the motor base and attaching it to the sander.

I saw the design for the base in one of the British knives forums. I can’t remember the name of the person who wrote the article. If someone do, please let me know and i will gladly give him his due credit.

This time it is not that important to cut it very precise, but make sure that the dimensions of the cutting will allow you to mount the motor.

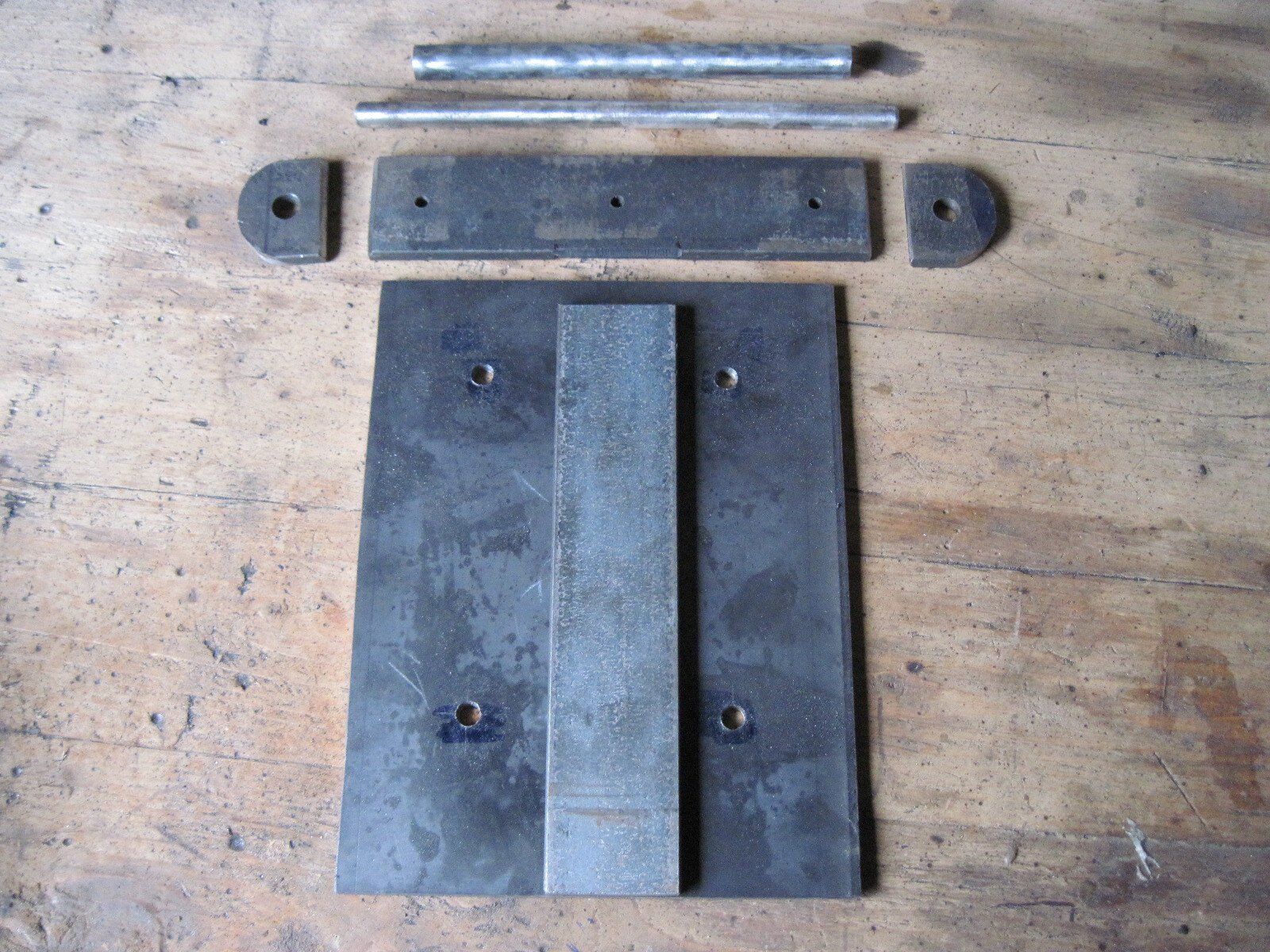

Begin by drill and thread all the necessary.

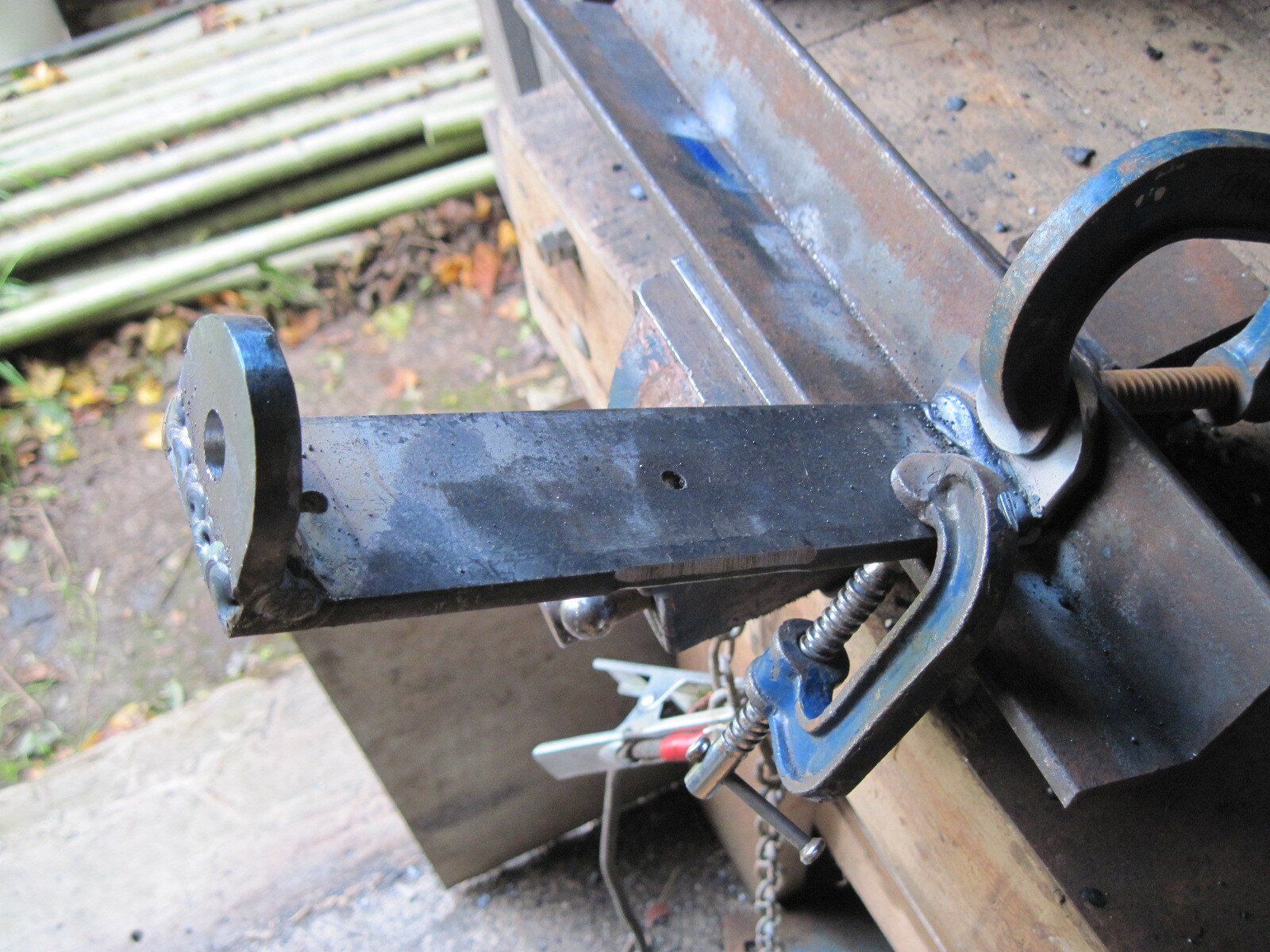

Then all you have to do is to weld parts (e) on top of part (c), then part (b) to part (c).

My best weld so far. Pity is through word the end of the construction

You will have to cut out the black parts of the prints. Use the sharpest and most pointy knife you can find.

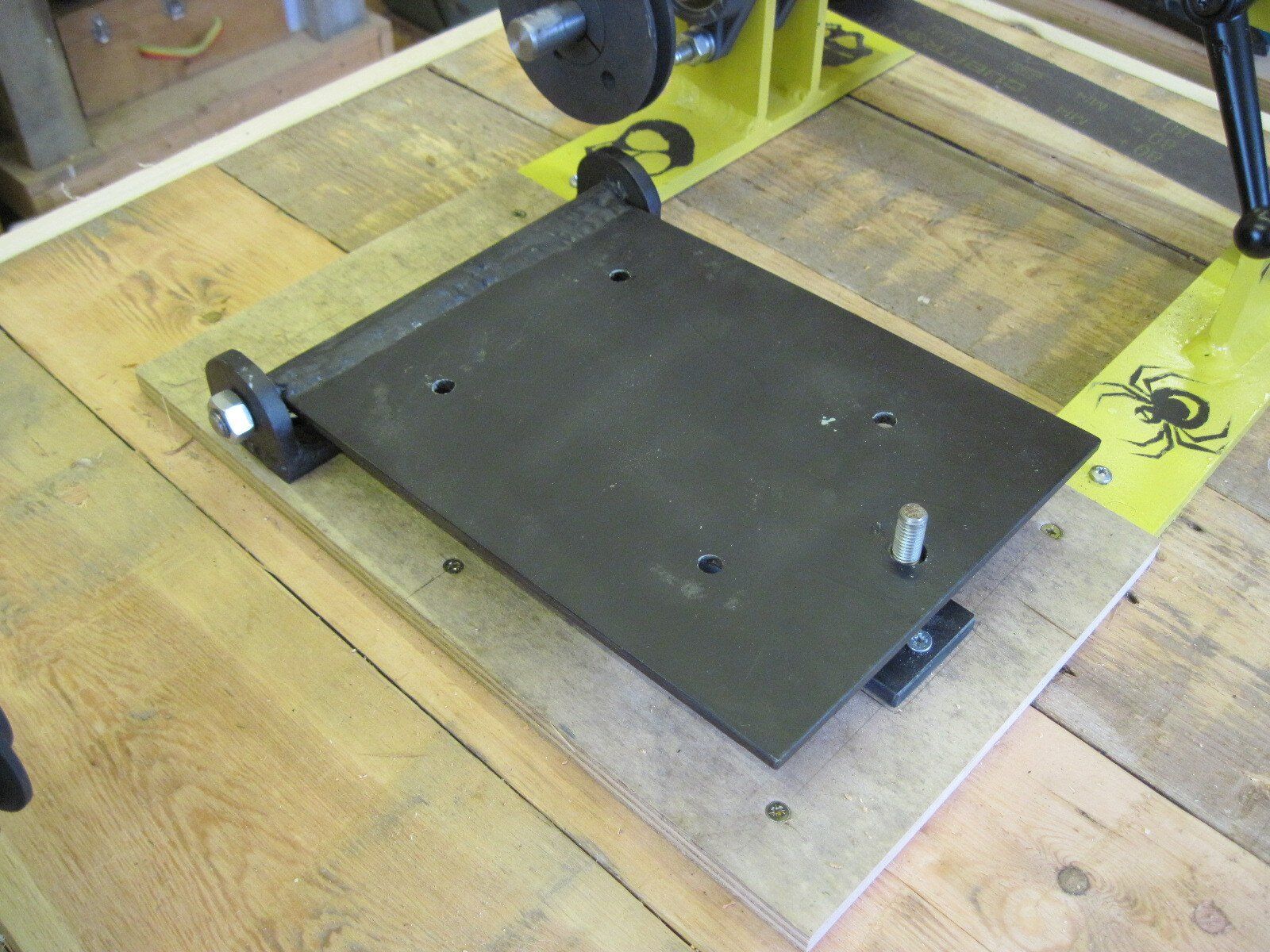

and your done.

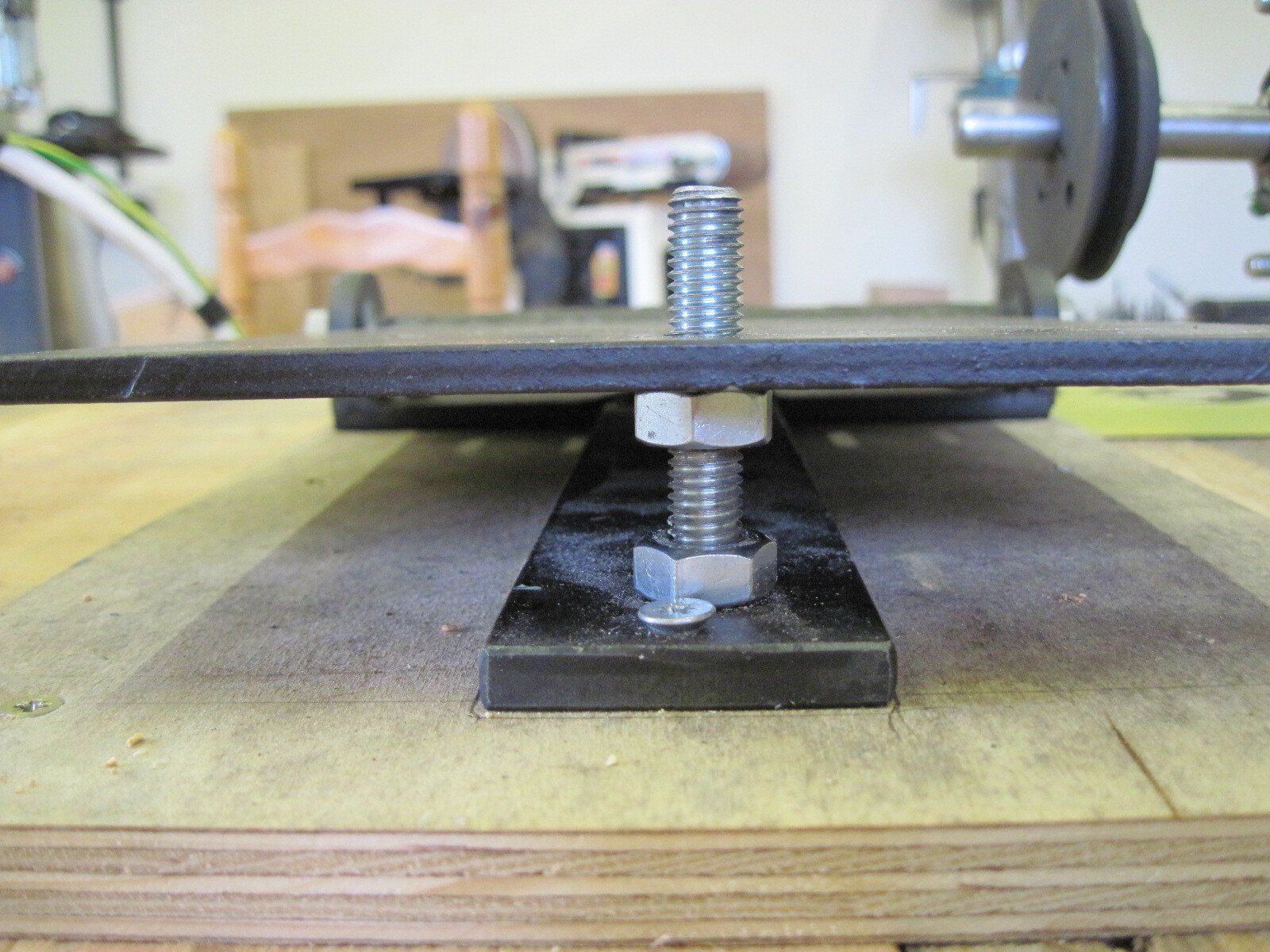

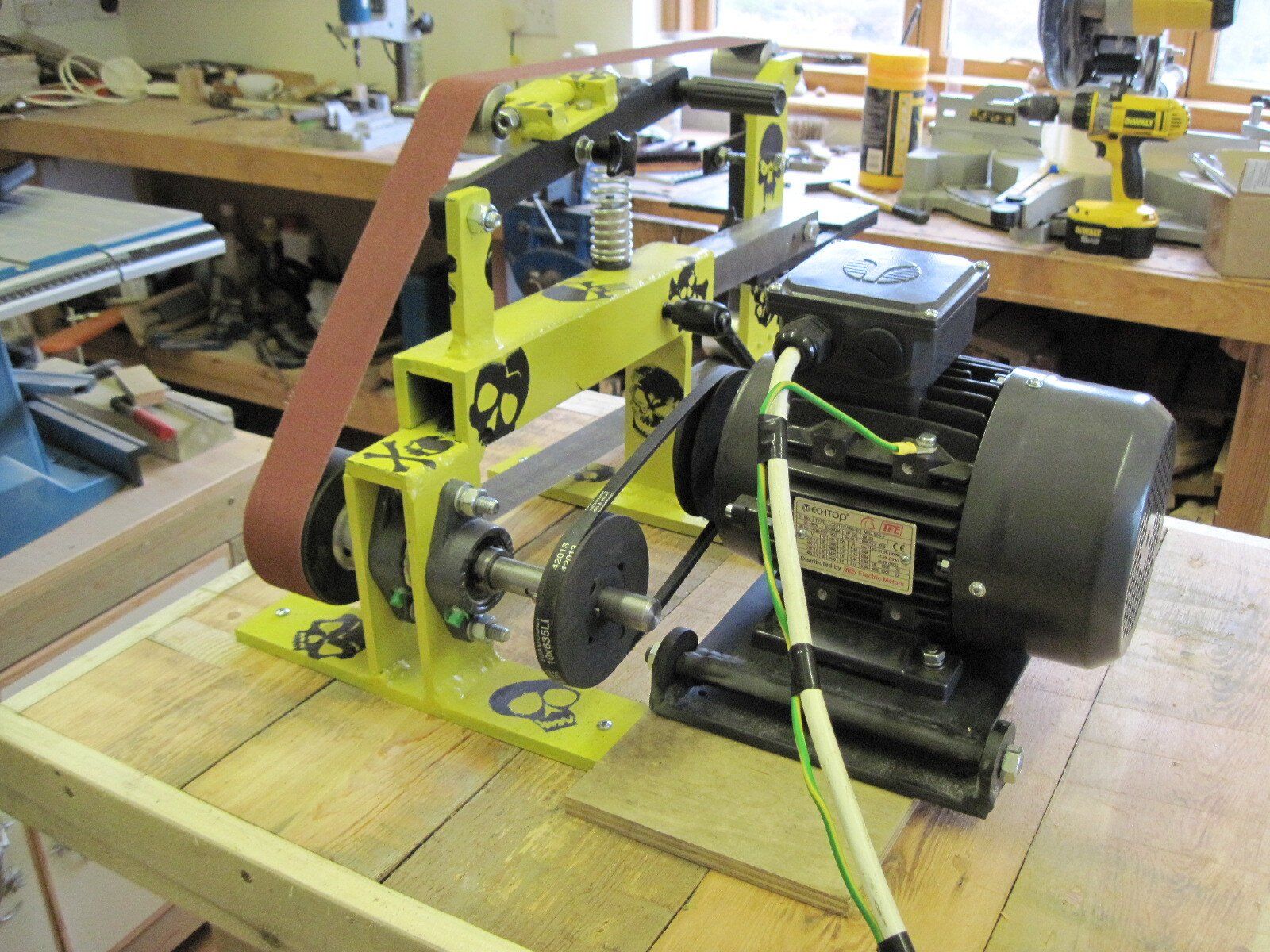

You don’t have to worry about how to tension the belt, as the weight of the motor will look after that.

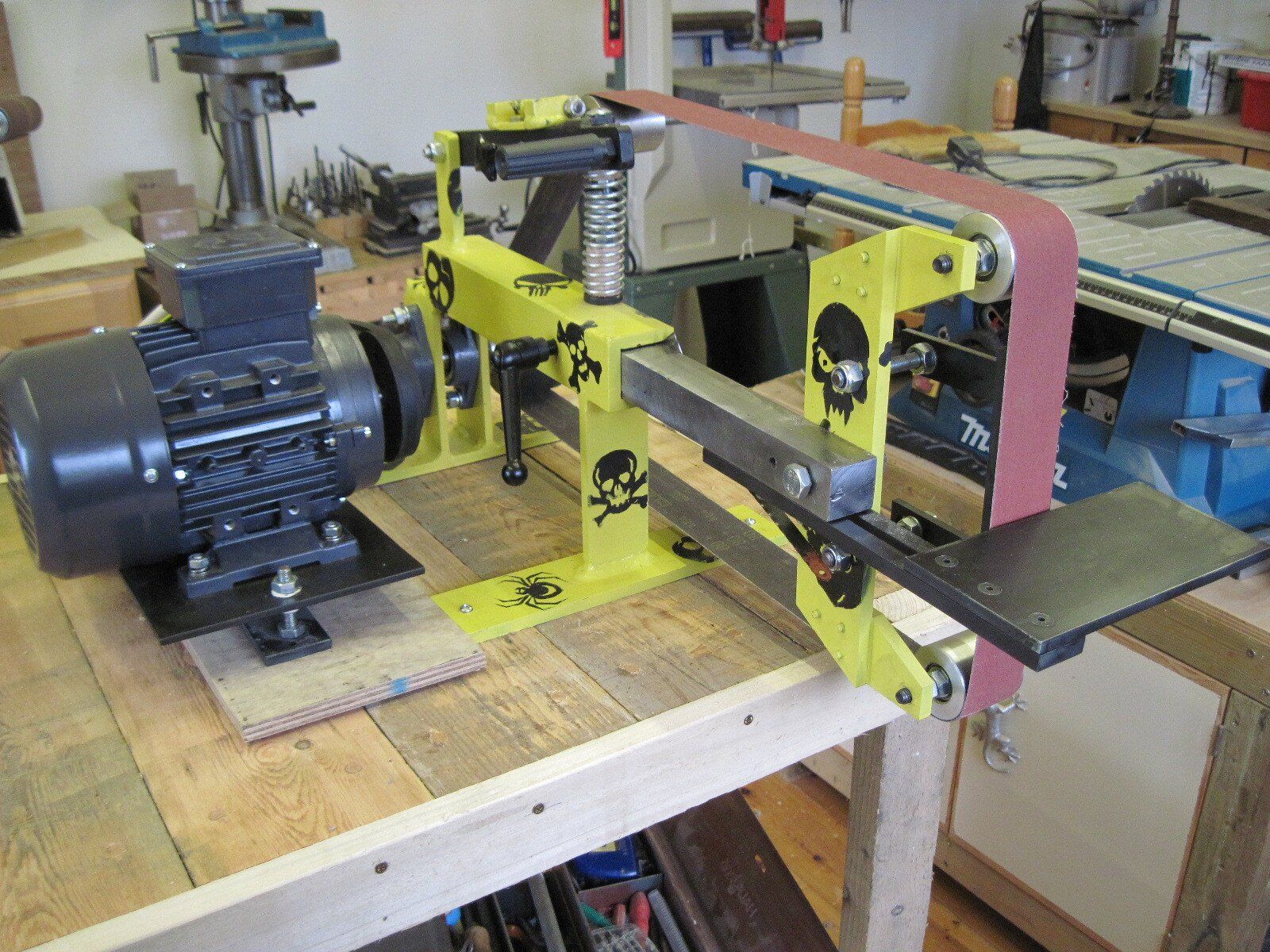

As you can see from the images I had to mount it on top of piece of wood. So or do better design or get piece of wood.

And finally, my pride and joy seat proudly on newly built work bench. All there is to do is to mount the electric box on the wall.

That it, but….. I will post another post in regards of The Belt sander. It’s going to be about commissioning the sander and some tips & tricks after few weeks of using it.

Bespoke knives and blacksmithing. Online shop and workshops

All Rights Reserved | RB Knifemaker